CARBIDE MINIATURE TAPERED END MILLS

FEATURES & BENEFITS

Regardless of their size, these end mills will rapidly and accurately remove material from precision and micro machining operations. The smart vibration dampening geometry, works to demonstrate almost surgical milling. This end mill is perfect for applications ranging from medical instruments to electronics. We persistently refine our engineering and after witnessing the results, one would be hard-pressed to find a better tool.

RESULTS

When the workload requires surgical precision, detail and tight tolerances, you can rely on our Conical Tapered Miniatures to be the most finely tuned tools in the industry. Our tapered minis hold tighter tolerances and create a more superior surface finish than traditional micro machining tools. Fabricated from the best performing micrograin carbide available, the Conical Tapered Miniatures provide the results you need, instead of extra stress you need to avoid

| CARBIDE TAPERED END MILL – MINIATURE | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ANGLE | DIAMETER | LENGTH | # OF FLUTES | UNCOATED* | |||||||||||

| PER SIDE | INCLUDED | TIP SIZE | LARGE END | SHANK | OF CUT | OVERALL | SQUARE END | BALL END | |||||||

| A | +0°30′ | D2 | +.002″ | D3 | D1 | L2 | +.100″ | L1 | PART # | EDP# | PART # | EDP# | |||

| -0°30′ | -.002″ | -.000″ | |||||||||||||

| 0.5° | 1° | 0.0313 | 0.0356 | 1/8 | 0.125 | 0.250 | 2.500 | 3 | CM-AX-0001 | – | CM-AX-0001-BE | – | |||

| 0.5° | 1° | 0.0313 | 0.0400 | 1/8 | 0.125 | 0.500 | 2.500 | 3 | CM-AX-0002 | – | CM-AX-0002-BE | – | |||

| 0.5° | 1° | 0.0469 | 0.0512 | 1/8 | 0.125 | 0.250 | 2.500 | 3 | CM-AX-011 | – | CM-AX-011-BE | – | |||

| 0.5° | 1° | 0.0469 | 0.0556 | 1/8 | 0.125 | 0.500 | 2.500 | 3 | CM-AX-012 | – | CM-AX-012-BE | – | |||

| 0.5° | 1° | 0.0625 | 0.0669 | 1/8 | 0.125 | 0.250 | 2.500 | 3 | CM-AX-001 | – | CM-AX-001-BE | – | |||

| 0.5° | 1° | 0.0625 | 0.0712 | 1/8 | 0.125 | 0.500 | 2.500 | 3 | CM-AX-002 | – | CM-AX-002-BE | – | |||

| 0.5° | 1° | 0.0625 | 0.0756 | 1/8 | 0.125 | 0.750 | 2.500 | 3 | CM-AX-003 | – | CM-AX-003-BE | – | |||

| 0.5° | 1° | 0.0625 | 0.0800 | 1/8 | 0.125 | 1.000 | 2.500 | 3 | CM-AX-004 | – | CM-AX-004-BE | – | |||

| 0.5° | 1° | 0.0781 | 0.0869 | 1/8 | 0.125 | 0.500 | 2.500 | 3 | CM-AX-022 | – | CM-AX-022-BE | – | |||

| 0.5° | 1° | 0.0781 | 0.0912 | 1/8 | 0.125 | 0.750 | 2.500 | 3 | CM-AX-023 | – | CM-AX-023-BE | – | |||

| 0.5° | 1° | 0.0781 | 0.0956 | 1/8 | 0.125 | 1.000 | 2.500 | 3 | CM-AX-024 | – | CM-AX-024-BE | – | |||

| 1° | 2° | 0.0313 | 0.0400 | 1/8 | 0.125 | 0.250 | 2.500 | 3 | CM-A-0001 | – | CM-A-0001-BE | – | |||

| 1° | 2° | 0.0313 | 0.0487 | 1/8 | 0.125 | 0.500 | 2.500 | 3 | CM-A-0002 | – | CM-A-0002-BE | – | |||

| 1° | 2° | 0.0469 | 0.0556 | 1/8 | 0.125 | 0.250 | 2.500 | 3 | CM-A-011 | – | CM-A-011-BE | – | |||

| 1° | 2° | 0.0469 | 0.0643 | 1/8 | 0.125 | 0.500 | 2.500 | 3 | CM-A-012 | – | CM-A-012-BE | – | |||

| 1° | 2° | 0.0625 | 0.0712 | 1/8 | 0.125 | 0.250 | 2.500 | 3 | CM-A-001 | – | CM-A-001-BE | – | |||

| 1° | 2° | 0.0625 | 0.0800 | 1/8 | 0.125 | 0.500 | 2.500 | 3 | CM-A-002 | – | CM-A-002-BE | – | |||

| 1° | 2° | 0.0625 | 0.0887 | 1/8 | 0.125 | 0.750 | 2.500 | 3 | CM-A-003 | – | CM-A-003-BE | – | |||

| 1° | 2° | 0.0625 | 0.0974 | 1/8 | 0.125 | 1.000 | 2.500 | 3 | CM-A-004 | – | CM-A-004-BE | – | |||

| 1° | 2° | 0.0781 | 0.0956 | 1/8 | 0.125 | 0.500 | 2.500 | 3 | CM-A-022 | – | CM-A-022-BE | – | |||

| 1° | 2° | 0.0781 | 0.1043 | 1/8 | 0.125 | 0.750 | 2.500 | 3 | CM-A-023 | – | CM-A-023-BE | – | |||

| 1° | 2° | 0.0781 | 0.1130 | 1/8 | 0.125 | 1.000 | 2.500 | 3 | CM-A-024 | – | CM-A-024-BE | – | |||

| 1.5° | 3° | 0.0313 | 0.0443 | 1/8 | 0.125 | 0.250 | 2.500 | 3 | CM-AAX-0001 | – | CM-AAX-0001-BE | – | |||

| 1.5° | 3° | 0.0313 | 0.0574 | 1/8 | 0.125 | 0.500 | 2.500 | 3 | CM-AAX-0002 | – | CM-AAX-0002-BE | – | |||

| 1.5° | 3° | 0.0469 | 0.0600 | 1/8 | 0.125 | 0.250 | 2.500 | 3 | CM-AAX-011 | – | CM-AAX-011-BE | – | |||

| 1.5° | 3° | 0.0469 | 0.0731 | 1/8 | 0.125 | 0.500 | 2.500 | 3 | CM-AAX-012 | – | CM-AAX-012-BE | – | |||

| 1.5° | 3° | 0.0625 | 0.0756 | 1/8 | 0.125 | 0.250 | 2.500 | 3 | CM-AAX-001 | – | CM-AAX-001-BE | – | |||

| 1.5° | 3° | 0.0625 | 0.0887 | 1/8 | 0.125 | 0.500 | 2.500 | 3 | CM-AAX-002 | – | CM-AAX-002-BE | – | |||

| 1.5° | 3° | 0.0625 | 0.1018 | 1/8 | 0.125 | 0.750 | 2.500 | 3 | CM-AAX-003 | – | CM-AAX-003-BE | – | |||

| 1.5° | 3° | 0.0625 | 0.1149 | 3/16 | 0.188 | 1.000 | 3.000 | 3 | CM-AAX-004 | – | CM-AAX-004-BE | – | |||

| 1.5° | 3° | 0.0781 | 0.1043 | 1/8 | 0.125 | 0.500 | 2.500 | 3 | CM-AAX-022 | – | CM-AAX-022-BE | – | |||

| 1.5° | 3° | 0.0781 | 0.1174 | 1/8 | 0.125 | 0.750 | 2.500 | 3 | CM-AAX-023 | – | CM-AAX-023-BE | – | |||

| 1.5° | 3° | 0.0781 | 0.1305 | 3/16 | 0.188 | 1.000 | 3.000 | 3 | CM-AAX-024 | – | CM-AAX-024-BE | – | |||

| 2° | 4° | 0.0313 | 0.0487 | 1/8 | 0.125 | 0.250 | 2.500 | 3 | CM-B-0001 | – | CM-B-0001-BE | – | |||

| 2° | 4° | 0.0313 | 0.0662 | 1/8 | 0.125 | 0.500 | 2.500 | 3 | CM-B-0002 | – | CM-B-0002-BE | – | |||

| 2° | 4° | 0.0469 | 0.0643 | 1/8 | 0.125 | 0.250 | 2.500 | 3 | CM-B-011 | – | CM-B-011-BE | – | |||

| 2° | 4° | 0.0469 | 0.0818 | 1/8 | 0.125 | 0.500 | 2.500 | 3 | CM-B-012 | – | CM-B-012-BE | – | |||

| 2° | 4° | 0.0625 | 0.0800 | 1/8 | 0.125 | 0.250 | 2.500 | 3 | CM-B-001 | – | CM-B-001-BE | – | |||

| 2° | 4° | 0.0625 | 0.0974 | 1/8 | 0.125 | 0.500 | 2.500 | 3 | CM-B-002 | – | CM-B-002-BE | – | |||

| 2° | 4° | 0.0625 | 0.1149 | 1/8 | 0.125 | 0.750 | 2.500 | 3 | CM-B-003 | – | CM-B-003-BE | – | |||

| 2° | 4° | 0.0625 | 0.1323 | 3/16 | 0.188 | 1.000 | 3.000 | 3 | CM-B-004 | – | CM-B-004-BE | – | |||

| 2° | 4° | 0.0781 | 0.1130 | 1/8 | 0.125 | 0.500 | 2.500 | 3 | CM-B-022 | – | CM-B-022-BE | – | |||

| 2° | 4° | 0.0781 | 0.1305 | 3/16 | 0.188 | 0.750 | 3.000 | 3 | CM-B-023 | – | CM-B-023-BE | – | |||

| 2° | 4° | 0.0781 | 0.1480 | 3/16 | 0.188 | 1.000 | 3.000 | 3 | CM-B-024 | – | CM-B-024-BE | – | |||

| 3° | 6° | 0.0313 | 0.0575 | 1/8 | 0.125 | 0.250 | 2.500 | 3 | CM-C-0001 | – | CM-C-0001-BE | – | |||

| 3° | 6° | 0.0313 | 0.0837 | 1/8 | 0.125 | 0.500 | 2.500 | 3 | CM-C-0002 | – | CM-C-0002-BE | – | |||

| 3° | 6° | 0.0469 | 0.0731 | 1/8 | 0.125 | 0.250 | 2.500 | 3 | CM-C-011 | – | CM-C-011-BE | – | |||

| 3° | 6° | 0.0469 | 0.993 | 1/8 | 0.125 | 0.500 | 2.500 | 3 | CM-C-012 | – | CM-C-012-BE | – | |||

| 3° | 6° | 0.0625 | 0.1149 | 1/8 | 0.125 | 0.500 | 2.500 | 3 | CM-C-001 | – | CM-C-001-BE | – | |||

| 3° | 6° | 0.0625 | 0.1149 | 1/8 | 0.125 | 0.500 | 2.500 | 3 | CM-C-002 | – | CM-C-002-BE | – | |||

| 3° | 6° | 0.0625 | 0.1411 | 3/16 | 0.188 | 0.750 | 3.000 | 3 | CM-C-003 | – | CM-C-003-BE | – | |||

| 3° | 6° | 0.0625 | 0.1673 | 3/16 | 0.188 | 1.000 | 3.000 | 3 | CM-C-004 | – | CM-C-004-BE | – | |||

| 3° | 6° | 0.0781 | 0.1305 | 3/16 | 0.188 | 0.500 | 3.000 | 3 | CM-C-022 | – | CM-C-022-BE | – | |||

| 3° | 6° | 0.0781 | 0.1567 | 3/16 | 0.188 | 0.750 | 3.000 | 3 | CM-C-023 | – | CM-C-023-BE | – | |||

| 3° | 6° | 0.0781 | 0.1829 | 3/16 | 0.188 | 1.000 | 3.000 | 3 | CM-C-024 | – | CM-C-024-BE | – | |||

| 5° | 10° | 0.0313 | 0.0750 | 1/8 | 0.125 | 0.250 | 2.500 | 3 | CM-E-0001 | – | CM-E-0001-BE | – | |||

| 5° | 10° | 0.0313 | 0.1187 | 3/16 | 0.188 | 0.500 | 3.000 | 3 | CM-E-0002 | – | CM-E-0002-BE | – | |||

| 5° | 10° | 0.0469 | 0.0906 | 1/8 | 0.125 | 0.250 | 2.500 | 3 | CM-E-011 | – | CM-E-011-BE | – | |||

| 5° | 10° | 0.0469 | 0.1344 | 3/16 | 0.188 | 0.500 | 3.000 | 3 | CM-E-012 | – | CM-E-012-BE | – | |||

| 5° | 10° | 0.0625 | 0.1062 | 1/8 | 0.125 | 0.250 | 2.500 | 3 | CM-E-001 | – | CM-E-001-BE | – | |||

| 5° | 10° | 0.0625 | 0.1500 | 1/4 | 0.250 | 0.500 | 2.500 | 3 | CM-E-002 | – | CM-E-002-BE | – | |||

| 5° | 10° | 0.0625 | 0.1937 | 1/4 | 0.250 | 0.750 | 2.500 | 3 | CM-E-003 | – | CM-E-003-BE | – | |||

| 5° | 10° | 0.0625 | 0.2375 | 1/4 | 0.250 | 1.000 | 2.500 | 3 | CM-E-004 | – | CM-E-004-BE | – | |||

| 5° | 10° | 0.0781 | 0.1656 | 3/16 | 0.188 | 0.500 | 3.000 | 3 | CM-E-022 | – | CM-E-022-BE | – | |||

| 5° | 10° | 0.0781 | 0.2094 | 1/4 | 0.125 | 0.750 | 2.500 | 3 | CM-E-023 | – | CM-E-023-BE | – | |||

| 5° | 10° | 0.0781 | 0.2531 | 3/8 | 0.375 | 1.000 | 2.500 | 3 | CM-E-024 | – | CM-E-024-BE | – | |||

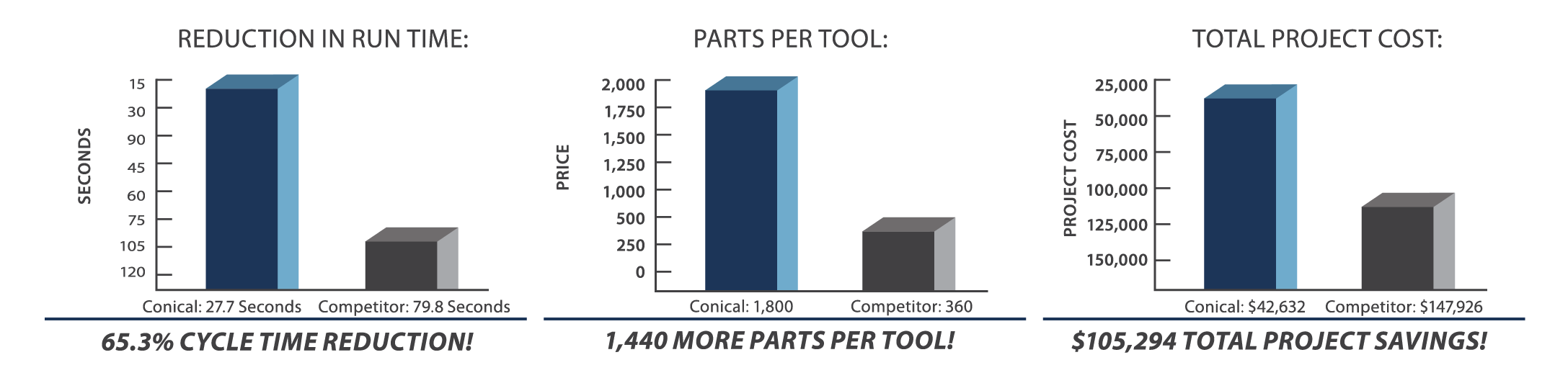

PRODUCTION ENHANCEMENTS

Proper tool setup and selection can improve your running parts by nearly 3 fold. Rather than using a 7 multi-axis machine and substantial programming time to cut a draft angle, the use of our tapered end mills were able to improve the finish and dramatically increase production results.