CARBIDE DIE SINK END MILLS

We have kept pace with ever changing technology, very strict CNC tooling quality demands and standard tolerances accepted by the aerospace industry and the Department of Defense. We have aggressively pursued the quest for greater end mill consistency, durability and performance. See for yourself.

| CARBIDE DIE SINK END MILLS – 5 DEGREES | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ANGLE | DIAMETER | LENGTH | # OF FLUTES | UNCOATED | |||||||||

| PER SIDE | INCLUDED | TIP SIZE | LARGE END | SHANK | OF CUT | OVERALL | |||||||

| A | +0°30′ | D2 | +.002″ | D3 | D1 | L2 | +.100″ | L1 | PART # | EDP# | |||

| -0°30′ | -.002″ | -.000″ | |||||||||||

| 5° | 10° | 0.0313 | – | 1/8 | 0.125 | 0.500 | 2.000 | 2 | DS2-E0001 | – | |||

| 5° | 10° | 0.0625 | – | 1/8 | 0.125 | 0.375 | 2.000 | 2 | DS2-E001 | – | |||

| 5° | 10° | 0.0625 | – | 3/16 | 0.188 | 0.688 | 2.000 | 2 | DS2-E002 | – | |||

| 5° | 10° | 0.0625 | – | 1/4 | 0.250 | 1.063 | 2.500 | 2 | DS2-E003 | – | |||

| 5° | 10° | 0.1250 | – | 1/4 | 0.250 | 0.688 | 2.500 | 2 | DS2-E201 | – | |||

| 5° | 10° | 0.0313 | – | 1/8 | 0.125 | 0.500 | 2.000 | 3 | DS3-E0001 | – | |||

| 5° | 10° | 0.0625 | – | 1/8 | 0.125 | 0.375 | 2.000 | 3 | DS3-E001 | – | |||

| 5° | 10° | 0.0625 | – | 0.188 | 0.688 | 2.000 | 3 | DS3-E002 | – | ||||

| 5° | 10° | 0.0625 | – | 1/4 | 0.250 | 1.063 | 2.500 | 3 | DS3-E003 | – | |||

| 5° | 10° | 0.1250 | – | 1/4 | 0.250 | 0.688 | 2.500 | 3 | DS3-E201 | – | |||

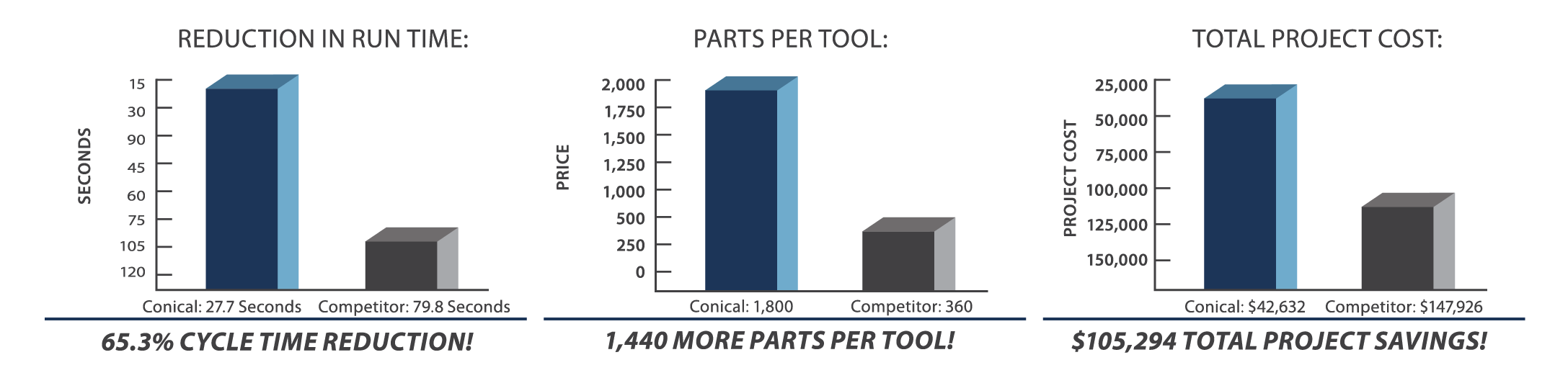

PRODUCTION ENHANCEMENTSProper tool setup and selection can improve your running parts by nearly 3 fold. Rather than using a 7 multi-axis machine and substantial programming time to cut a draft angle, the use of our tapered end mills were able to improve the finish and dramatically increase production results.